Waterfall Screen Solutions

ClearBlu manufacturers wastewater screens as a highly efficient and cost-effective alternative to other solids removal systems. There are a number of factors that make our wedge wire screens an excellent choice.

Why Choose Our Screens?

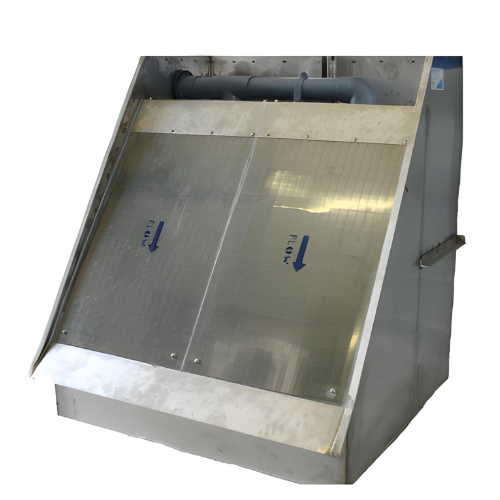

- The screens have a very steep angle. This allows water flow to push screened material off into a dewatering hopper.

- .5 mm screens will actually separate material as small as .25 mm.

- Automatic spray bars keep dried material from clogging the wedge wire screens. Because they are timer-activated, they use 90% less water than rotary screens.

- Stainless steel construction means acidic wastewater is no challenge.

- Screening solids before pH balancing can reduce chemical consumption by 60%. Solids can soak up significant amounts of the chemical.

What makes a good waterfall filter?

There are several important factors in selecting a good waterfall filter:

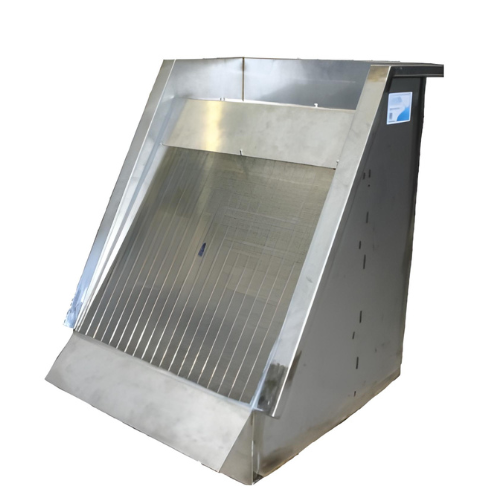

- The spacing between the wedge wire bars can vary.

- The top of the wedge wire is flat (wedge wire is made of flattened tubing) and the tops should be canted slightly so that they trap the water.

- There needs to be sufficient runway at the top so that the water can gain velocity. This is accomplished by placing a smooth section of stainless just below the weir at the top.

- The slope of the wedge wire needs to be steep. This is counterintuitive. It would seem that you would want a low slope to slow the water. Instead, you want a steep slope so that you don’t build up solids on the wedge wire screen. Water is heavy and will pass through a steep screen.