Lift Stations Explained: What They are and how they work

WHat is a lift station?

Lift stations are used in both municipal and industrial settings to prevent wastewater from backing up and to keep systems flowing efficiently. By using powerful pumps and automated controls, they ensure wastewater is transported safely and reliably—no matter the elevation challenges.

types of Lift stations

There are two main types of lift stations, each with its own configuration and advantages:

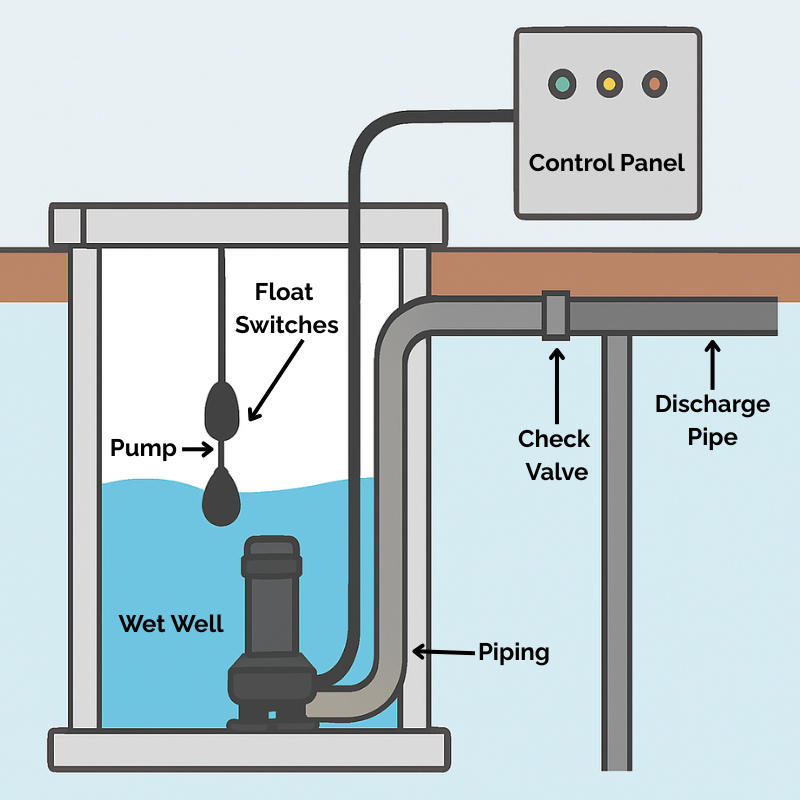

- Wet Well Lift Stations: These systems collect wastewater in a basin (or “wet well”) and use float switches or level sensors to activate pumps when the water reaches a certain level.

- Dry Well Lift Stations: In this setup, the pumps and controls are housed in a separate, dry chamber next to the wet well. These are often used in larger or more complex installations.

Submersible pumps are the most common type used today, especially in wet well systems, because they are efficient and require less space.

Key Components

- Wet Well: The basin where wastewater is collected before being pumped.

- Pumps: Typically submersible, they push wastewater to higher elevations or directly into the main sewer system.

- Float Switches or Level Sensors: Detect the water level in the wet well and trigger the pump.

- Control Panel: The brains of the system, managing when pumps activate and monitoring system health.

- Check Valves & Piping: Direct flow and prevent backflow during operation.

These components work together to ensure continuous and reliable wastewater transport. Whether it’s handling high volumes from a food processing facility or overcoming gravity in a remote commercial development, lift stations are engineered to keep everything flowing.

how do lift stations work?

The process is automated, efficient, and designed to handle continuous flow.

Here’s how it works:

- Collection – Wastewater flows into a wet well, a holding tank where it’s temporarily stored.

- Level Detection – Float switches or level sensors monitor the water level. When it rises to a set point, they signal the pumps to turn on.

- Pumping – Submersible pumps push the wastewater upward through discharge piping, allowing it to continue toward the main sewer line or treatment facility.

- Flow Control – Check valves prevent backflow, and the system shuts off automatically once levels drop back down.

Lift stations are built to run reliably with minimal manual intervention. For industrial or high-volume applications, ClearBlu can design custom lift station systems to meet demanding performance and maintenance needs.

Why lift stations matter and who needs them

Lift stations play a critical role in wastewater management. Whether it’s flat terrain, low-lying buildings, or remote locations, these systems ensure wastewater keeps moving—safely, efficiently, and in compliance with regulations.

Why lift stations are necessary

- Overcome Elevation Challenges– When a facility sits below the level of the main sewer or treatment plant, a lift station pumps wastewater up to where it needs to go.

- Avoid Costly Trenching– In long-distance applications, lift stations reduce the need for deep, expensive excavation by allowing for shallower piping routes.

- Prevent Sewage Backup– By maintaining steady flow, lift stations help avoid the serious risks of wastewater backing up into a facility.

- Ensure Regulatory Compliance– Industrial operations often face strict wastewater handling requirements. Lift stations help meet those standards reliably.

WHo Uses lift stations?

Lift stations are essential for a wide range of industries and businesses:

- Food and Beverage Processing

- Wineries and Breweries

- Commercial Developments

- Industrial Facilities

- Municipal Systems

If your operation involves wastewater and faces elevation or distance challenges, a lift station could be the most efficient and cost-effective solution.

The key advantages

A well-designed lift station doesn’t just move wastewater—it helps your entire system run more efficiently, safely, and cost-effectively. Here are some of the main benefits:

- Improved Wastewater Flow

- Low Infrastructure Costs

- Smaller Footprint

- Automation and Reliability

- Regulatory Compliance

Choosing a lift station

Selecting the right lift station starts with understanding your site’s specific needs. One of the most important factors is flow rate—how much wastewater your system needs to handle on a daily basis. This will determine the size of the wet well and the type of pumps required.

Another key consideration is elevation. If your lift station needs to pump wastewater over a significant vertical distance, you’ll need a more powerful pump and a system designed to handle the pressure.

The type of wastewater also matters. Industrial or food processing operations often deal with solids, grease, or high-strength waste, which can affect pump choice and may require solids separation equipment upstream.

Space limitations can also influence the design. Some locations benefit from compact or submersible lift stations that take up minimal room and are easier to maintain.

Finally, consider how much automation and monitoring you need. Many modern systems offer remote monitoring and smart controls, which help catch issues early and reduce downtime.

At ClearBlu, we help clients choose and build lift stations that match their exact site conditions, flow requirements, and long-term goals.

ClearBlu Solutions

Partnering with Topp Industries, we provide high-quality fiberglass basins that offer several advantages over traditional concrete structures. Fiberglass basins are lightweight, making them easier to install, and their corrosion-resistant properties ensure durability in acidic environments where concrete might deteriorate. Additionally, these basins can be conveniently fitted with high-temperature pumps and pre-plumbed with rail kits for streamlined installation.

In addition to fiberglass basins, ClearBlu offers duplexing lift stations from Topp Industries. These systems incorporate two pumps operating in sequence to ensure redundancy and enhance efficiency. The control systems alternate between the pumps, extending their lifespan, and can activate both pumps simultaneously during high inflow situations. Customization options include visual and audible alarms for failure alerts and dry contacts for remote monitoring via Wi-Fi or cellular connections.

ClearBlu’s lift stations are versatile, capable of handling flows ranging from intermittent small volumes to thousands of gallons per minute. They can be configured with stainless steel rail kits, pumps, and plumbing to withstand harsh conditions, ensuring long-lasting performance.

conclusion

Lift stations are essential for reliable, efficient wastewater management—especially when gravity flow isn’t an option. From industrial facilities to food and beverage operations, the right lift station can reduce costs, prevent backups, and keep you in compliance.

At ClearBlu Environmental, we specialize in designing and supporting custom lift station systems built to meet the specific needs of your operation. Whether you’re upgrading an existing system or planning a new installation, our team is here to help.

Explore more wastewater solutions and contact us today to discuss your lift station needs.