industries served

fOOD PROCESSORS

Our custom solutions will effectively treat all your wastewater. Our systems can easily grow and expand with your business. Trust the experienced professionals at ClearBlu for all your facility needs.

Wastewater Treatment for food processors

Food processors generally discharge very large quantities of wastewater. Most discharge streams contain high quantities of organic matter creating high BOD, TSS and TDS counts. ClearBlu can typically reduce BOD and TSS by 85% to 97%. With non-chemical sterilization, we can make your wastewater usable for cleaning, irrigation, and dust control. For some question and answers from the California State Water Resources Control Board, check out this PDF.

System Implementation

Systems can be implemented in stages, depending on the changing and growing needs of the facility. The systems are also easily expandable, allowing for lower initial capital investment for facilities that are lower production or just starting out. The system can grow as the facility grows.

Pretreatment components include customized lift stations, solids separation, and pH balancing. While the treatment portion of the system is easily expandable, pretreatment components are recommended to be sized for the maximum projected production level of the facility, therefore rendering upgrades unnecessary as the facility grows.

Lift Stations

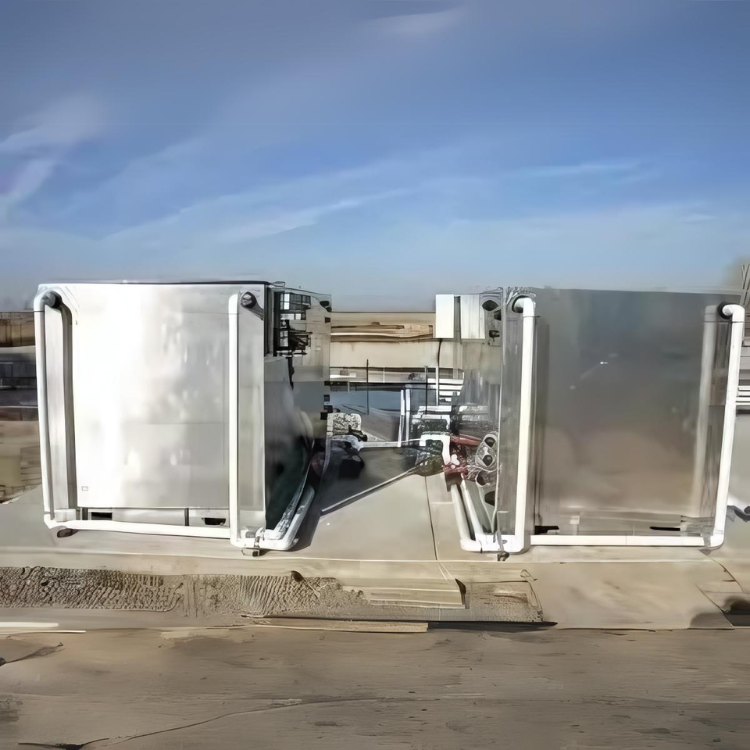

Lift stations are tailored to the specific needs of the facility’s waste stream. We take into consideration factors such as pH, temperature, and flow rate of the waste stream to design a lift station that will be the most efficient and durable for even the harshest of wastewater. Options such as high-temperature and/or stainless steel sump pumps, vinyl ester linings, duplexing lift stations, and audible/visual alarm systems are among the many customizable features of our lift stations.

Solids Separation

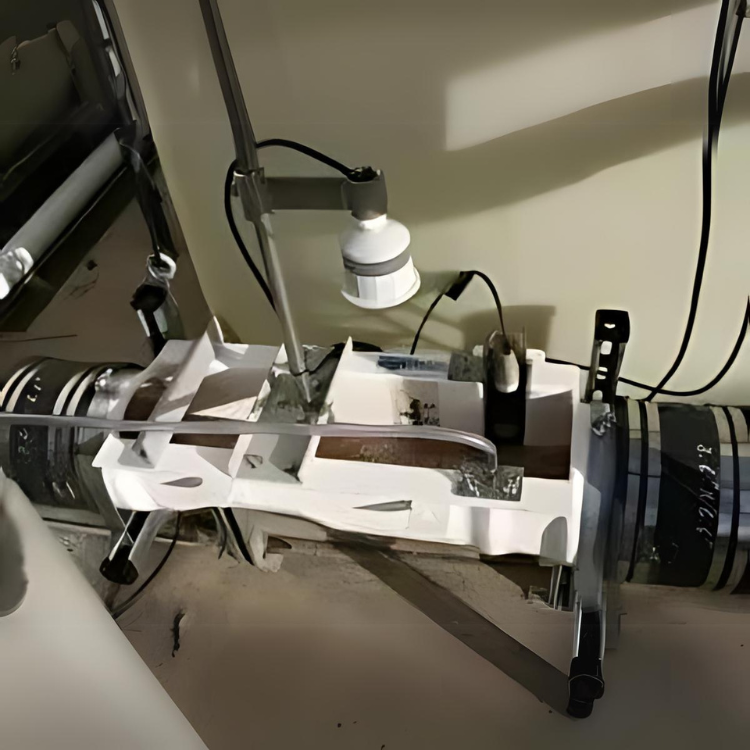

Solids separation is accomplished through the use of gravity flow waterfall hydroscreens. Through years of development and continued improvements, ClearBlu has designed a simple and highly effective means of separating solids that requires no or low energy and very little maintenance. Wastewater is lifted into the stainless steel unit where water gravity flows over a wedgewire screen that is set at an angle. The wedgewire catches solids which slough off the front and drop into a dewatering hopper, while the screened water passes through the wedgewire and on to the next stage of the system.

Many applications benefit from the addition of an automatic spraybar system to help keep the wedgewire clean and free from blinding. These spraybars operate on a timer to ensure that water use is kept to a minimum. Our spraybar system can reduce water use by up to 90% over traditional rotary drum screens and has significantly fewer parts that require maintenance.

Screening out solids both protects subsequent components of the treatment system as well as reducing chemical use significantly during pH balancing. Solids removal is also an important step to aid in the efficient treatment of wastewater via aerobic digestion.

pH Balancing

pH balancing is an important step of pretreatment. Many sewer districts require only solids separation and/or pH balancing prior to discharge into the sewer systems, and if full treatment is desired then pH balancing is critical for successful aerobic digestion. Once wastewater has excess solids removed, pH balancing requires fewer chemicals, as solids tend to act as a sponge and soak up the chemical.

Our experience has shown that up to (XX%) less chemical is used if solids separation is implemented. Since ClearBlu systems utilize aerobic digestion for wastewater treatment, a pH between 6-10 is required for a hospitable environment for bacteria to digest organic material.

ClearBlu has designed ruggedized automatic pH balancing systems to accommodate a wide variety of flow rates. They employ digital controls and programming to facilitate in maintaining a narrow pH range that allows for minimal chemical consumption. Stainless steel mixing eductors ensure that water is adequately mixed in real-time, preventing over or under-correction.

The digital pH sensor is fitted with a compressed air cleaning system that prevents binding that can occur quickly in wastewater environments. A variable speed chemical pump operates on a 4 to 20 mV system that allows for finite dosing of balancing chemical. These systems are small footprint with large capabilities.

Aerobic Treatment

Aerobic treatment is accomplished by using energy efficient microbubble aerators to create a highly oxygenated environment that allows bacteria to thrive. With excess organic solids removed and a neutral pH, ClearBlu’s customized blend of pseudomonas and bacillus bacteria (microbes) can efficiently digest organic material to meet discharge requirements and enable water reuse if desired.

This aerobic process can digest through existing layers of organic sludge in ponds or tanks, thus avoiding the need for costly dredging procedures if existing organic sludge is an issue.

Another benefit of an aerobic system is that the process is odor free, as the bacteria’s byproduct of digestion is carbon dioxide and not foul smelling methane or sulfide compounds as with anaerobic digestion.

CONTACT US

TALK WITH AN EXPERT

We have a cost-effective and environmentally friendly solution for operations of all shapes and sizes in the United States.

Contact Us – Sidebar

FAQS

How much sludge do your systems generate?

Our systems are designed to minimize sludge generation and will even digest organic sludge. While “facultative” systems only aerate the top few feet of water, our micro and nanobubble systems generate non-buoyant bubbles to completely aerate the entire water column, enabling our high-strength bacteria to digest organics in the water, and on the sludge layer.

What causes wastewater system odor?

The most common causes of process wastewater odor are low pH causing the water to go septic, as well as insufficient aeration. ClearBlu’s automatic pH balancing systems and microbubble aeration ensure odor is kept at bay even during harvest.

Do your systems require full-time operators?

Generally, no! ClearBlu designs systems that are ruggedized, simple to operate, and low on maintenance. A typical ClearBlu wastewater system does NOT require a full-time operator. We often service on a monthly or bi-monthly basis to check things like motor amp draw, pH, and DO levels, as well as overall equipment condition.

Do you have info on California Regulations?

GET STARTED

Have more questions, or need to help deciding which equipment is right for you? Our team is here to assist.

key Benefits

ClearBlu offers highly customizable solutions for the wastewater treatment needs of food processors. Choosing a ClearBlu treatment system offers multiple cost-saving benefits:

1

Reduced Risk & Labor

Expensive pump and haul events are reduced or eliminated. Full-time operators are not necessary, resulting in decreased overhead for system operation.

2

Eliminate Surcharges

Sewer surcharges incurred from exceeding discharge parameters can be eliminated.

3

Water & Energy Savings

Up to 70% energy savings can be accomplished by switching from outdated and inefficient technologies – energy rebates are frequently obtained.

4

Exceed Treatment Goals

Reduce your BOD and TSS by up to 98% while also lowering treatment time from months to days.

5

Chemical Costs

Chemical costs are reduced over systems that require flocculent or coagulant, also eliminating hazardous materials hauling fees.

6

Manage Sludge Effectively

Prevent new organic sludge buildup in your ponds and tanks. Avoid dredging costs and solids removal procedures by digesting existing sludge.

CASE STUDIES

Take a look at businesses we’ve helped across the world. See why our wastewater treatment is the most trusted and efficient solution available.

Garrison Brewing

Project Type: Pre-Treatment

Equipment: Lift Stations; Waterfall Screens

Learn More

Daou Vineyards and Winery

Project Type: Primary Treatment

Equipment: Lift Stations; Waterfall Screens; pH Balancing; Settling Tanks

Learn More

Rouge Ale & Spirits

Project Type: Full Treatment

Equipment: Lift Stations; Waterfall Screens; Dewatering Hoppers; pH Balancing; Settling Tanks;

Learn More

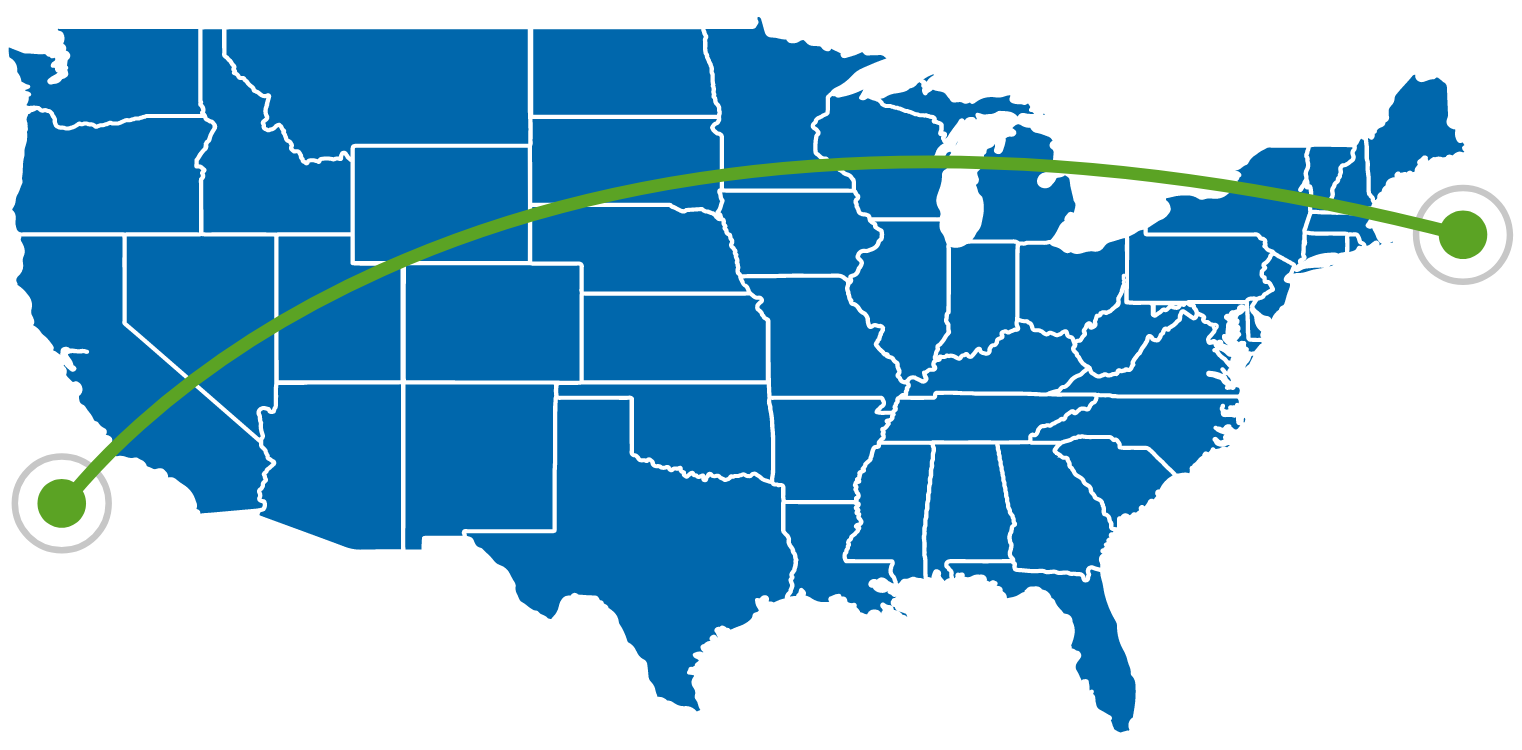

CONVENIENT LOCATIONS

Serving Companies Nationally

With locations in California, Colorado, and Oregon, we are able to provide wastewater treatment solutions across the United States.

full service

our EQUIPMENT

ClearBlu provides sophisticated wastewater treatment for food processors of all sizes. We can help with everything from compliance to efficiency.