Pre-Treatment

Showing all 6 results

-

Solids Separation3 Phase SeparatorsUseSolids Separation

Solids Separation3 Phase SeparatorsUseSolids Separation -

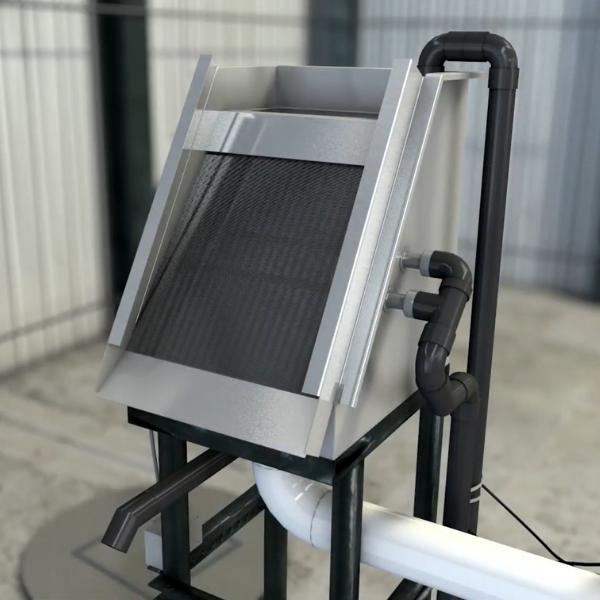

Pre-TreatmentDewatering HoppersUseN/A

Pre-TreatmentDewatering HoppersUseN/A -

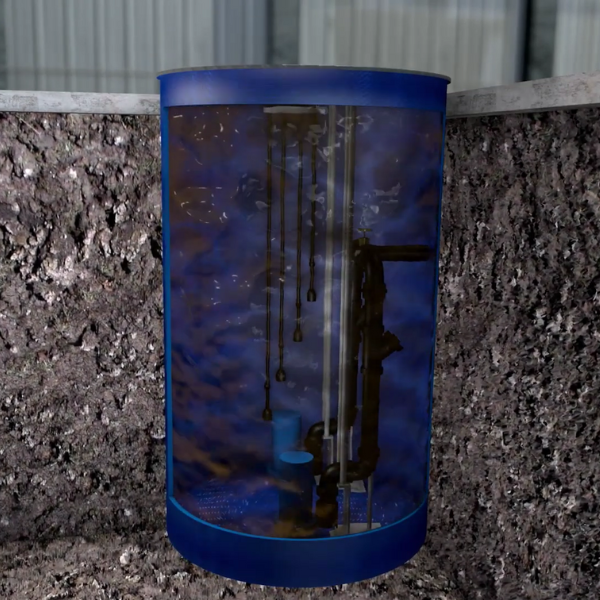

Pre-TreatmentLift StationsUseN/A

Pre-TreatmentLift StationsUseN/A -

Pre-TreatmentpH BalancingUseN/A

Pre-TreatmentpH BalancingUseN/A -

Solids SeparationSettling TanksUseSolids Separation

Solids SeparationSettling TanksUseSolids Separation -

Solids SeparationWaterfall ScreensUseSolids Separation

Solids SeparationWaterfall ScreensUseSolids Separation

Showing all 6 results