industries served

wash bays

Effective. Simple. Easy to operate. You’ll appreciate the care we take to custom design our industrial wash bays. We know every customer is different. ClearBlu will create the ideal solution for your unique needs and applications.

Wastewater Treatment for wash bays

ClearBlu Environmental specializes in industrial wash bay treatment systems designed to be used in harsh conditions for a wide variety of industries. From heavy equipment dealers, garbage companies, agricultural, rental yards, municipalities, golf courses and more.

Our wash bay systems maintain a consistent design across industries, yet are customized to suit individual needs. For a simpler and less labor-intensive way to operate, turn to ClearBlu Environmental wash bay systems.

Facility Uses

A facility that has sewer access may be required to treat wash bay wastewater either to comply with discharge requirements or to reduce sewer fees. ClearBlu treatment systems have proven for years that they are effective at removing solids and consistently meeting oil and grease discharge requirements, even under the strictest regulations.

With Sewer Access

ClearBlu treatment systems have proven for years that they are effective at removing solids and consistently meeting oil and grease discharge requirements, even under the strictest regulations.

Without Sewer Access

Some facilities do not have access to sewer or want to reduce their environmental impact. In this case we can reclaim wastewater to reuse it and lower the water consumption, lowering cost as well. For these customers, we employ what is called a full reclaim wastewater treatment system. The only water that leaves the system is via evaporation, overspray, and drive-off and the rest is continuously treated and recycled. It can then be used again in high volume washers or hot pressure washers.

When the system runs low on water, fresh water solenoid valves operate on demand to add fresh water and bring the system back to an acceptable level. Some systems can be designed with rainwater storage tanks that collect rainwater when the system runs low. Full reclaim systems may choose to employ a small cold pressure washer that operates on freshwater for a final clean rinse of their vehicles.

CONTACT US

TALK WITH AN EXPERT

We have a cost-effective and environmentally friendly solution for businesses of all shapes and sizes in the United States.

Contact Us – Sidebar

FAQS

Why does my wash bay smell?

Wash bay odor can be caused by the oils and greases trapped in the system which are not being properly treated. ClearBlu uses aeration and high-strength microbes to ensure that wash water is fresh, clear and odor-free for re-use or discharge.

What makes ClearBlu wash bays different from others?

ClearBlu has decades of experience designing wash bays that are simple, durable and effective. Every year we incorporate new improvements into our designs, and our customers will tell you that the difference is in performance – our systems simply work. We can handle heavy mud, oil and grease, strict discharge requirements, spot-free rinse or even fully closed loop reclaim. Every wash bay is different, and we design them all from the ground up.

Do you offer portable options for wash bays?

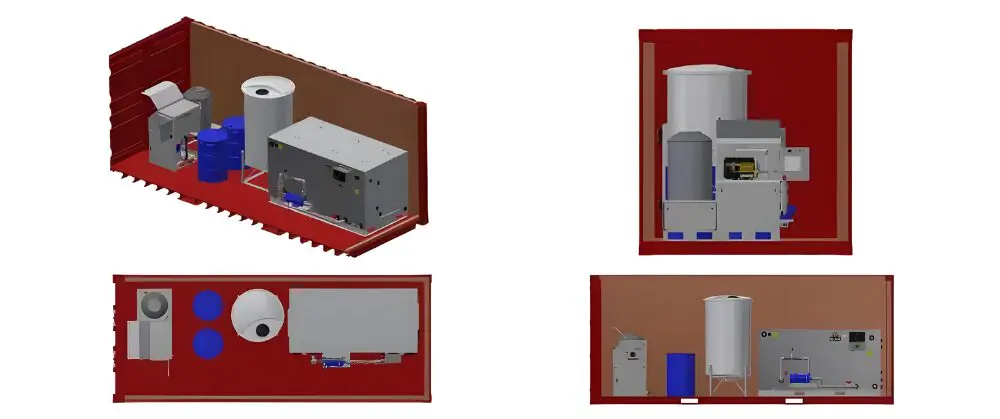

Yes! Clearblu offers a self-contained treatment system for equipment washwater treatment and reclamation. This system can work well in conjunction with a drive-in pit, or 3 phase separator for heavy mud applications, or on its own for moderate to low mud applications.

The 20-foot container size makes the unit easy to move and install and to relocate at a later day. The unit can be used in conjunction with a ClearBlu portable washpad for complete flexibility.

GET STARTED

Have more questions, or need to help deciding which equipment is right for you? Our team is here to assist.

Key Features

A ClearBlu wash bay treatment system have unique features that set them apart from other available technologies. This includes above ground, automated mud handling, biodigester technology, and completely ruggedized construction for system longevity.

1

Automated Mud Handling

We resign existing systems, design completely new systems, and work with regulatory agencies, contractors, architects, and engineers

Read More

Above ground, mud handling is accomplished by utilizing a self-cleaning lift station in conjunction with cone bottom settling tanks fitted with automatic pinch valve assemblies. All wastewater, mud, sand, small debris, grease, and oil are lifted into the above-ground settling tanks to accomplish a few important things. The solids that are captured by the system are rendered nonhazardous because all the grease and oil floats to the top of the tank while the solids settle to the bottom of the cone, where they are automatically purged into mud hoppers. This can save a tremendous amount of money because the dried mud can be sent to the landfill or land applied rather than paying to haul hazardous material. Additionally, by moving all solids into an above ground tank, the need for a costly third-party pump and haul events of in-ground separator vaults becomes unnecessary since all mud handling can be accomplished in-house.

2

Biodigester Technology

Biodigester Technology utilizes power aeration and specialized bacteria to break down all hydrocarbons that enter the system. ClearBlu Environmental specializes in durable industrial wash bay treatment systems for numerous industries such as heavy equipment dealers, garbage companies, and more.

Read More

Our expertise extends to agricultural, rental yards, municipalities, and golf courses, offering comprehensive solutions for their specific needs. The main design concepts for systems across all industries remain the same, however, each system is tailored to meet the needs of each specific customer. ClearBlu is able to differentiate from other wash bay treatment systems in a few key ways that allow them to be more effective, simpler, and less labor intensive to operate as compared to other systems.

3

Ruggedized Construction

Ruggedized construction of ClearBlu equipment wash bay systems is an important benefit to consider. The industry standard for wash bay treatment systems is typically between 5 and 7 years.

Read More

ClearBlu has put in years of research and development to design a system with a projected lifespan of 20 years. Our lift stations are fitted with a steel perf plate lid over the drive on a grate to keep out all large debris that can destroy pumps. All pumps employed are industrial cast iron construction and are rebuildable to handle the harsh conditions they will endure. Additionally, systems utilize all schedule 40 or 80 PVC rather than a hose to increase longevity, and all key plumbing is mounted on Unistrut.

ClearBlu wash bays offer customization for facilities discharging treated wastewater or reclaiming it for reuse. Both systems employ similar technologies, but a reclaim system may have enhanced solids settling and longer retention time.

CASE STUDIES

Our systems are applicable to any size business. We build completely new systems as well as retrofit existing systems. Browse through case studies below.

RDO Equipment

Project Type: Primary Treatment

Equipment: Settling Tanks; Biodigesters; Wastewater Aeration;

Learn More

Heavy Equipment

Project Type: Primary Treatment

Equipment: Settling Tanks; Wastewater Aeration; Biodigesters; Microbes;

Learn More

Testimonials

Discover the impact of our custom wash bay designs through the eyes of those who matter most – our clients. These testimonial videos showcase real stories and experiences, highlighting the effectiveness and innovation of our solutions in diverse industrial settings.

RDO Equipment Company

Scott Williams, the Environmental Compliance Manager at RDO Equipment Company talks about how ClearBlu Environmental helps them meet compliance and save on cost.

Watch Video

Sea Mist & Ocean Mist Farms

Don Brocco, the Maintenance Manager at Sea Mist & Ocean talks about how ClearBlu Environmental helps them meet compliance and save on cost.

Watch Video

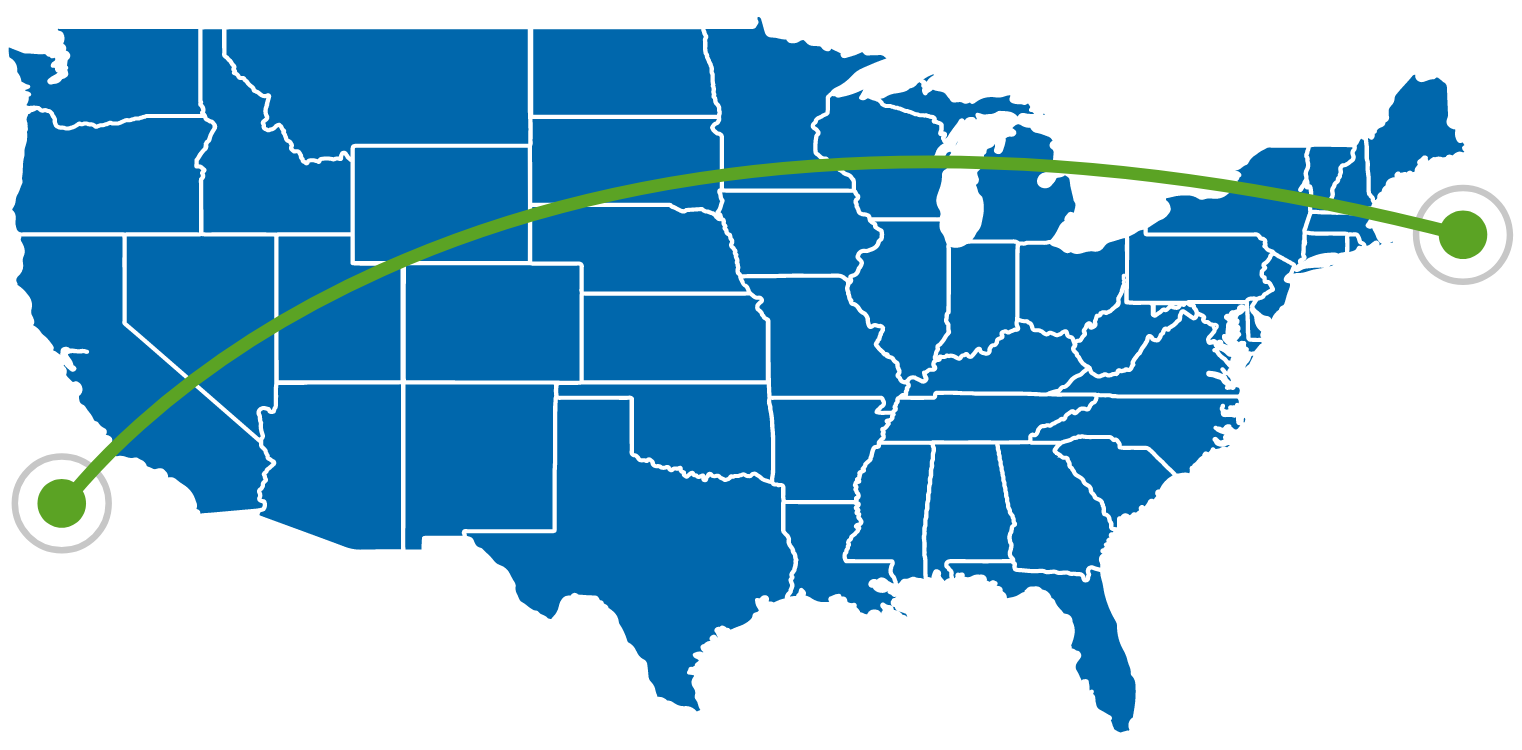

CONVENIENT LOCATIONS

Serving Companies Nationally

With locations in California, Colorado, and Oregon, we are able to provide wastewater treatment solutions across the United States.

Sponsored by The Mi-T-M Corporation